Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Rotary drive fixed bracket welding

Place Of Origin: China

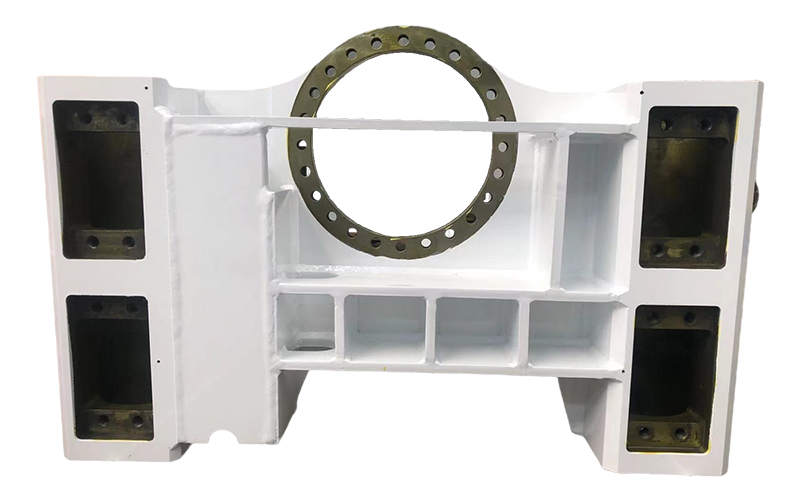

Name: Rotary drive fixed support welded A

Size: 1134mm*735mm*220mm

Weight: 387.69 kg

| Selling Units: | Others |

Professional processing of rotary drive fixed bracket

Product introduction:

1. Preparation before processing: For the processing of the fixed support of the rotary drive, it is first necessary to carry out the preparation before processing, including the debugging and inspection of the processing equipment, the selection and inspection of the processing tools, and the preparation and inspection of the processing materials.

2. Processing accuracy control: the rotary drive fixed bracket is a precision component, whose processing accuracy directly affects its service effect and life. Therefore, it is necessary to strictly control the machining accuracy, including dimensional accuracy, shape and position accuracy, surface roughness, etc.

3. Processing technology control: the processing technology of the rotary drive fixed bracket is very important, including processing sequence, processing parameters, processing speed, processing fluid, etc. It is necessary to determine the appropriate processing technology according to the specific processing requirements and material characteristics to ensure the processing quality and efficiency.

4. Selection of processing equipment: Some special processing equipment, such as CNC machine tools, grinders, milling machines, are required for the processing of rotary drive fixed supports. It is necessary to select appropriate processing equipment according to processing requirements and material characteristics, and conduct equipment commissioning and inspection to ensure processing quality and efficiency.

5. Selection of processing materials: The processing materials of the rotary drive fixed bracket are usually high-strength and high-hardness alloy steel or stainless steel. It is necessary to select suitable processing materials according to processing requirements and material characteristics, and conduct material inspection and treatment to ensure processing quality and efficiency.

6. Processing process monitoring: The processing process of rotary drive fixed support needs to be monitored in real time, including processing quality, processing efficiency, equipment status, etc. It needs to be adjusted and optimized according to the actual situation to ensure the processing quality and efficiency.

Product parameters:

Name: Rotary drive fixed support welded A

Size: 1134mm*735mm*220mm

Weight: 387.69 kg

Product picture:

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.